Aerospace PPAP & APQP Solution - Power Continual Improvement from VOC to FAI and FRACAS

Omnex brings our specialized methodologies for Risk Management, Aerospace APQP/PPAP (AS9145), New Product Launch and Characteristic Classification that we have practiced for over 26 years. We offer training in AS9102 First Article Inspection, AS9103 Variation Management of Key Characteristics and other Aerospace requirements.

We are pleased to introduce you to the Omnex Systems Aerospace APQP Solution in compliance to Aerospace PPAP and APQP (AS9145 & AS13004)

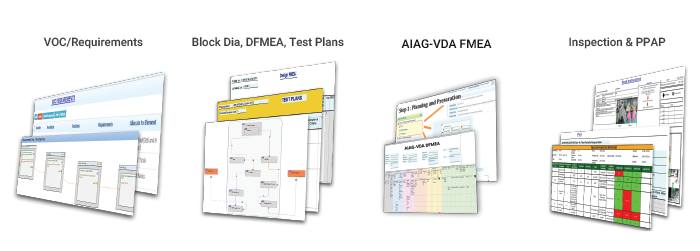

Manage Voice of Customer (VOC) Requirements

Build Block Diagrams, P-Diagram, DFMEA and Test Plans

Automate Process Flow, PFMEA and Control Plan, Checksheets & Work Instructions

Link to Inspection, First Article and PPAP Documents

Drive effective problem solving, failure analysis and feedback at all stages of development.

Effectively Track Entire Lifecycle VOC to FAI & PPAP

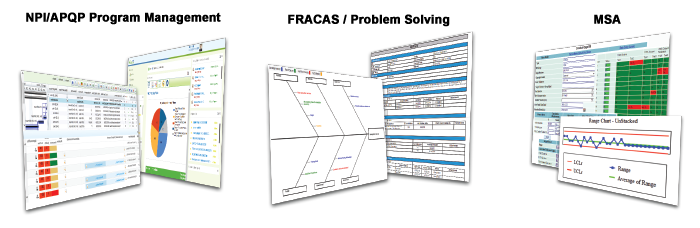

Manage New Product Introduction with a structured approach, concept to problem solving

Track all activities via a single pane of glass ensuring Command and Control of New Product Introduction

![]() The Voice of the Customer (VOC) is captured accurately, completely and any (unknown) project needs to consider unintended outcomes. A formal VOC process via EwQIMS Module Requirements Flowdown achieves this goal. Ensure Requirements Traceability of Requirements in the BOM (Bill of Material)

The Voice of the Customer (VOC) is captured accurately, completely and any (unknown) project needs to consider unintended outcomes. A formal VOC process via EwQIMS Module Requirements Flowdown achieves this goal. Ensure Requirements Traceability of Requirements in the BOM (Bill of Material)

![]() Advanced Quality Planning with APQP defines a structured way of defining the necessary steps to enhance new product releases thereby optimizing time, cost and quality. Customer satisfaction is guaranteed, lead times are shortened and program costs are minimized. AQuAPro® from Omnex is an integrated system of tools built on a common database to drive effective APQP and Design FMEA, Test Plans, Process Flow Process FMEA, Control Plan. read more

Advanced Quality Planning with APQP defines a structured way of defining the necessary steps to enhance new product releases thereby optimizing time, cost and quality. Customer satisfaction is guaranteed, lead times are shortened and program costs are minimized. AQuAPro® from Omnex is an integrated system of tools built on a common database to drive effective APQP and Design FMEA, Test Plans, Process Flow Process FMEA, Control Plan. read more

![]() Effective control over Product Lifecycle Management with easy to report schedule performance will ensure your project portfolio is tracked and resourced correctly, all viewable through a single pane of glass. Tasks can be assigned and Meetings used to drive their closure ensure your projects are completed on time and on budget. read more

Effective control over Product Lifecycle Management with easy to report schedule performance will ensure your project portfolio is tracked and resourced correctly, all viewable through a single pane of glass. Tasks can be assigned and Meetings used to drive their closure ensure your projects are completed on time and on budget. read more

![]() Manage your Incoming/Receiving, In-Process & Outgoing/Final Inspections by creating Part Family structures to efficiently plan Inspection. Reduce Operator learning curve by adapting pre-built Inspection Control documents adapted to your local preference. Track and manage cost of poor quality with BI integrated tools, reports and dashboards.

Manage your Incoming/Receiving, In-Process & Outgoing/Final Inspections by creating Part Family structures to efficiently plan Inspection. Reduce Operator learning curve by adapting pre-built Inspection Control documents adapted to your local preference. Track and manage cost of poor quality with BI integrated tools, reports and dashboards.

![]() Manage First Article Inspection FAI efficiently via an integrated relationship database that is accessible to your supplier community. read more

Manage First Article Inspection FAI efficiently via an integrated relationship database that is accessible to your supplier community. read more

![]() Drive an effective Failure Reporting and Corrective Action System (FRACAS) using tools that suit your business and the risks you face. Configurable business processes enable effective closure of failure reports. read more

Drive an effective Failure Reporting and Corrective Action System (FRACAS) using tools that suit your business and the risks you face. Configurable business processes enable effective closure of failure reports. read more