Complete Traceability from Voice of Customer to Component

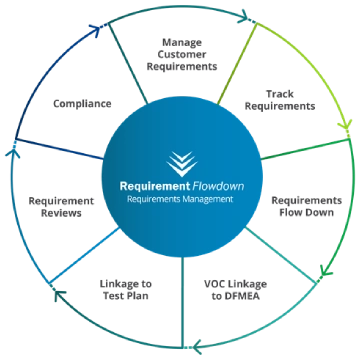

Requirements Flowdown Software

Identifying, documenting, structuring, and managing customer requirements and voice of customers before developing and launching any new product is a laborious and challenging task., Requirements Flowdown (RFD) software helps you achieve this with ease. The functions, requirements, and characteristics can be managed effectively right from the system, subsystem, all the way to the component levels.

RFD uses two robust systems, where data is structured by part families called the Production Item, and by the Bill of Material (BOM) which includes the Voice of Customer (VOC). RFD uses the V-Model to establish traceability of requirements within the system, subsystem, component, and Hardware & Software.