LPA Software

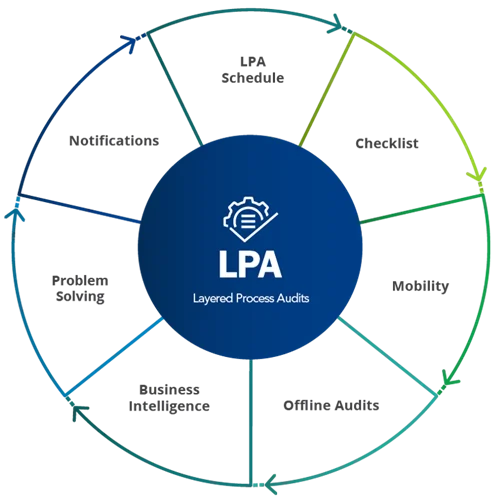

LPA software allows you to manage the audits at multiple levels within a company. Layers, frequency, auditors, and checklists can be defined in LPA software setup. Based on this information, layered process audits are scheduled by LPA software.

Layered Process Audit is a form of internal audits that focus on the critical manufacturing processes. Multiple levels of organizational personnel, including top management, can perform these audits.

Users can define the layers, frequency, duration, the number of auditors involved, whether they need an approver, and create checklists defining machines and production lines.

Layered Process Audit software is compliant with the following standards:

- IATF 16949

- CQI–8

Omnex Systems has successfully completed the SOC 2 Certification, reinforcing our commitment to maintaining the highest standards of data security and privacy for our clients.

View All certifications