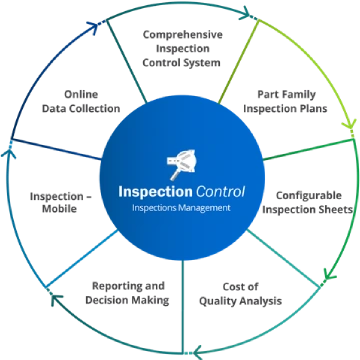

Inspection Control Software

A complex process, product, and supplier structure demands effective planning as the basis for quality regulation and quality inspection.

Using our Part Inspection Control software can ensure product quality control and standardize the shop floor and incoming inspection process. Our three models: Incoming/Receiving, In Process Inspection, and Final Inspection make the task simple.

Inspection Control Integration with AQuA Pro helps in managing processes from (R&D) Process Development Control and Incoming Inspection.

Once Design/Process documents released, users can initiate In-Process Inspection Worksheets and enter details such as:

- Characteristic Dimensional Requirements

- Tolerances/Specifications

- Evaluation Techniques

- Sample Frequency and

- Sample Size

Inspection control software is compliant with the following standards:

- IATF 16949

- AS 9145

Omnex Systems has successfully completed the SOC 2 Certification, reinforcing our commitment to maintaining the highest standards of data security and privacy for our clients.

View All certifications