Simplify PPAP documentation

AQuA Pro Software

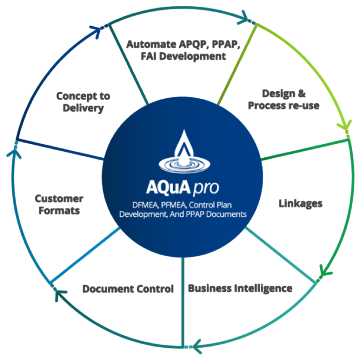

AQuA Pro is user-friendly software that integrates FMEA into APQP (Advanced Product Quality Planning), PPAP (Production Part Approval Process), and connects to Process Flow and Control Plan. It simplifies and documents the product development process while complying with industry standards.

Introduction to AQuA Pro

A web-based database management application, it assists in creating, maintaining, analyzing, and organizing your documents. This tool helps you develop your documents step-by-step for the APQP process. It was first introduced in 1985 and has continually evolved. Today, you can customize it to fit your preferred format. It serves as a valuable tool in optimizing your processes.

The APQP process helps you develop your documents from design to manufacturing. You will work with the Part of Families and V-model, enabling you to reuse process information, identify functions & requirements, and analyze Failure-Cause-Effect relationship in the BOM (Bill of Material).

AQuA Pro software is compliant with the following standards:

- AIAG VDA 1st Edition

- AIAG FMEA 4th Edition

- PPAP 4th Edition

- IATF 16949

- Aerospace AS9145 & AS13004

- ISO 13485

- SAE J1739

Omnex Systems has successfully completed the SOC 2 Certification, reinforcing our commitment to maintaining the highest standards of data security and privacy for our clients.

View All certificationsSpeakers:

Chad Kymal, Antony John

Watch RecordingSpeakers:

Medhat Habashi ,Antony John

Watch WebinarSpeakers:

Sarah Hathaway, Mary Rowzee

Watch RecordingSpeakers:

Nikhil Unnikrishnan, Gregory Gruska

Watch Recording