TPM Pro Software

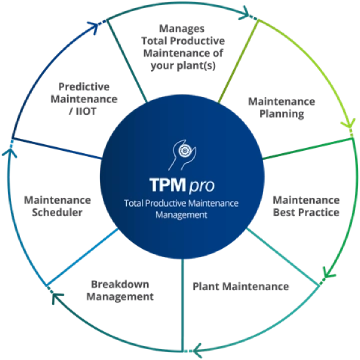

TPM Pro is a complete solution to manage, monitor, and control all maintenance activities in the Process or Manufacturing Industries. It supports the Total Productive Maintenance (TPM) approach by providing proactive information online for machinery and maintenance related data.

TPM Pro automates preventive maintenance and work order scheduling, while capturing the best practices in maintenance, formalizing them, and making them available across the enterprise. TPM Pro also provides comprehensive and accurate data on maintenance costs (both direct and indirect).

This data helps you monitor maintenance costs and plan maintenance budgets.

TPM Pro software is compliant with the following standards:

- IATF 16949

- TPM

Omnex Systems has successfully completed the SOC 2 Certification, reinforcing our commitment to maintaining the highest standards of data security and privacy for our clients.

View All certifications