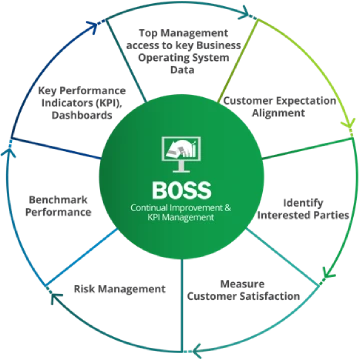

Most organizations rely on fragmented spreadsheets and manual reports. BOSS replaces those with a cloud-based hub for vision- and mission-based goal tracking, stakeholder mapping and risk management, so you always have a single source of truth.

BOSS Software

BOSS® or Business Operating System Software ® enables companies to apply a logical order to operational data. Generally, companies are data-rich and analysis-poor. When available data is overlooked, it is difficult to formulate solutions and maximize a company's full potential. BOSS® provides a data structure for problem-solving and decision analysis in easy-to-read formats.

With BOSS, companies can align customer expectations to key processes, leading to improvement. Tracks measurables from compliance to customer needs, thereby encouraging continuous improvement. Handles customer satisfaction and drives business excellence & continuous improvements.

BOSS software is compliant with the following standards:

- IATF 16949

- AS9145

- ISO 13485

- ISO 9001

- ISO 14001

- ISO 45001

- ISO 27001 and many more

Omnex Systems has successfully completed the SOC 2 Certification, reinforcing our commitment to maintaining the highest standards of data security and privacy for our clients.

View All certifications